|

|

|

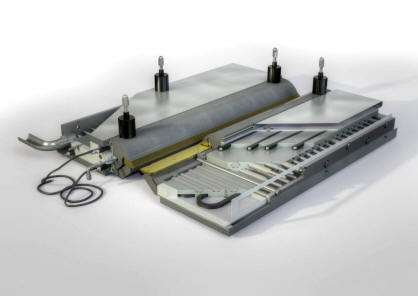

5 degree Air Knife: To download a brochure in PDF format click here |

|

| The new airknives for the Quicksilver leveler are a modified version of the successful design developed for the 'Alchemy' horizontal leveler. The airknives have a cast iron block at the front end, which is bolted to an aluminium heat exchanger of a similar design to the standard Quicksilver airknife. There are no gaskets needed anywhere in the assembly. The airknife tips are supplied as an assembled unit with the air gap pre-set. The tips can be separated for cleaning, and no re-gapping is required on re-assembly. Tip assemblies are the same for front and rear airknife. They are removed and replaced through an aperture in the side of the airknife cover and are clamped into the cast iron head block by 8 bolts. Changing tips can be accomplished in less than 15 minutes. The design of the head assembly prevents flux residues and carbon from penetrating into the aluminium heat exchanger, which ensures an extended operating life with minimum maintenance. The air jets have a downwards angle of 5 degree's from the horizontal, which reduces fumes and solder spatter to a considerable degree, while providing optimum leveling performance. Customer experience indicates improved quality on surface mount features, good hole clearing capability, and a high degree of 'controllability' - ie. alterations to pressure and/or gap settings produce predictable, repeatable changes to the solder finish. The 5 degree Quicksilver airknives are fitted as standard on new machines, or can be retro-fitted to machines currently in use. Retrofit installation by a trained Cemco engineer is recommended. Key Benefits

|